How a Flat Roof Is Built: Step-by-Step Guide to Joists, Noggins, and Falls

- Staff Desk

- Nov 4

- 8 min read

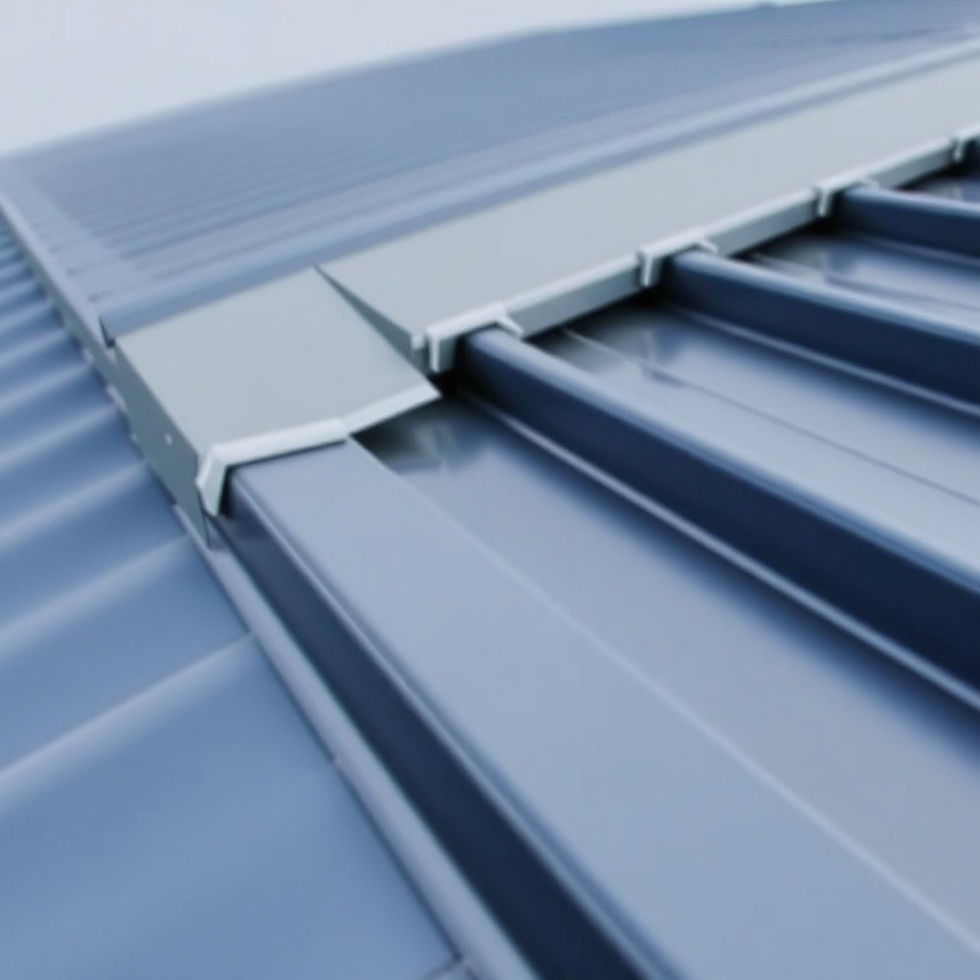

Flat roofs are a popular choice for modern homes and extensions, especially when adding roof lanterns or skylights. A well-built flat roof provides a clean, contemporary look, allows for good insulation, and can last for decades with proper construction and maintenance.

This article explains how a professional team sets out, assembles, and finishes the structural timber framework of a flat roof — including joists, noggins, upstands, and furring strips — and how everything works together to create strength, drainage, and precision.

Understanding the Basics of a Flat Roof

A flat roof is not completely flat. It has a very gentle slope, called a fall, that allows rainwater to flow toward a gutter or gully. The fall is usually between 1:40 and 1:80, depending on design and drainage layout. Flat roofs are built using a timber framework that supports the waterproof layers. The main parts include:

Joists – The horizontal structural members that form the base of the roof.

Noggins – Short pieces of timber placed between joists for strength and rigidity.

Trimmers – Extra joists used to reinforce openings (such as roof lanterns).

Upstands – Raised edges that form the perimeter and support flashing or glazing frames.

Furring strips – Tapered timbers that create the slope for drainage.

Each part plays a role in supporting weight, keeping the roof stable, and ensuring water runs off properly.

Setting Out the Joists

The first step is to set out the roof joists according to the structural design and the position of any roof lanterns or openings.

Joists are laid out evenly across the roof area, usually spaced 400 mm or 600 mm apart. Before fixing, the builder checks the specification for the roof lantern or skylight to make sure the joist layout matches its required opening size.

Key Points

Joists must be level, evenly spaced, and square to the walls.

The area where the roof lantern will sit is carefully measured and marked.

The outer edges are left stepped back slightly from the wall to allow space for plasterboard and internal finishes.

This careful setup ensures that later steps — insulation, decking, and roofing — fit neatly and stay watertight.

Installing and Securing the Joists

Once marked, the joists are installed. Each one is cut to size, positioned, and screwed or bolted into place.

Professionals often use screws instead of nails for better precision and future adjustments. Screws allow for fine-tuning the position if something needs to shift slightly, which is especially useful in roof construction.

Why Screwing Is Preferred

Easier to remove or adjust if needed.

Reduces vibration and movement compared to nails.

Provides stronger and more controlled fixing.

All joists are checked with a spirit level to ensure they sit perfectly straight across the span. Even a small dip can cause water pooling later, so accuracy at this stage is critical.

Adding Double Trimmers and Perimeter Noggins

After the main joists are in place, double trimmers are added around openings like roof lanterns. Trimmers strengthen the edges of these cut-outs and distribute the load evenly across the structure.

Perimeter Noggins

Around the outer edges, perimeter noggins are installed. These are small timber blocks placed between joists to stiffen the frame and provide a secure fixing point for plasterboard or ceiling finishes inside the room.

Perimeter noggins are typically stepped about 1 inch away from the wall or steel beam. This small gap allows room for internal plaster finishes and ensures everything aligns cleanly later.

Installing Internal Noggins

Once the perimeter is done, noggins are placed between the middle joists across the roof. These strengthen the structure and stop the joists from twisting or bowing over time.

The noggins also provide extra support for decking boards or insulation panels that will be fitted above. Each noggin is cut tightly to fit and screwed into place. Consistent spacing makes for a solid, stable roof deck.

Checking and Leveling the Frame

Before moving on, the entire framework is checked for level and alignment. A long straight edge or laser level is used to ensure every part lines up perfectly.

Even high-quality timber can have slight variations. Builders will often plane down high spots or sand out minor lips between timbers so that the surface is completely flat. This prevents unevenness when laying decking boards and avoids weak points in the waterproofing later.

Building Upstands Around Openings

Upstands are vertical timbers built around the perimeter of openings like roof lanterns. They create a raised edge that supports glazing frames and prevents water from entering.

Upstands also define the height of the lantern or skylight above the main roof surface. They are usually built using the same timber as the joists, securely fixed, and aligned flush with the trimmers.

Important Details

The upstand width should match the trimmer thickness.

Corners must be square and level.

Pilot holes are pre-drilled before screwing to prevent the timber from splitting.

After fixing, levels are checked again to confirm the upstands are even and straight.

Why Pilot Holes Are Used

Pilot holes are small pre-drilled holes that make it easier to drive screws into wood. They prevent the timber from splitting and allow for precise alignment.

In roof framing, pre-drilling helps keep the structure tight and accurate. It’s a small step that saves time and avoids damage, especially when working with hardwood or engineered timber.

Temporary Fixing and Testing Levels

Before permanently fastening every piece, builders often temporarily screw sections together to test the alignment and slope.

A spirit level or laser level is used to confirm everything is consistent. The builder makes minor adjustments until the frame sits perfectly level (except for the planned fall direction).

Once confirmed, all screws are driven in fully and checked again for tightness.

Screwing vs. Nailing

While both screws and nails are acceptable in timber framing, screws have clear advantages in precision work like roof construction.

Screws: Ideal for fine adjustments, easy to remove or reposition.

Nails: Faster for large framing jobs but harder to adjust later.

For roof structures, many professionals prefer screws, especially near delicate joins, upstands, and trimmers. This results in a cleaner finish and more control.

Finishing the Timber Framework

After the joists, noggins, and upstands are completed, the flat roof structure is solid, level, and ready for decking.

Before moving on, builders clean the work area and inspect all fixings. Screws should sit slightly below the surface (a few millimeters at most), ensuring no protrusions will interfere with the decking sheets.

Creating Falls With Furring Strips

Flat roofs need a fall — a slight slope that directs water toward a gully, drain, or outlet. To achieve this, builders use furring strips, which are long tapered timber pieces laid on top of the joists.

Each strip is cut so that one end is higher than the other, creating a gradual slope.

In this project, the roof had six separate falls, all converging into a single gully point where water will drain away. Each furring strip was hand-cut individually to match the specific slope direction.

How Furring Strips Work

They adjust the height of each joist line to create the correct slope.

They make sure rainwater flows evenly toward the drainage point.

They keep the surface smooth and stable for the decking boards above.

Accurate cutting and placement of furring strips are essential for good drainage and preventing ponding water.

Understanding Roof Falls and Gullies

A roof fall is the gradual angle that directs rainwater across the surface. The fall rate is designed to prevent standing water, which can cause leaks, rot, and premature membrane failure. All falls should lead toward a gully, which collects and channels water into downpipes or drains. In this setup, all six slopes guide water toward one central gully. This design minimizes outlets while ensuring proper drainage.

Overboarding With Plywood

Once the furring strips are in place, the next step is to overboard the roof with plywood decking. High-quality 9mm or 12mm hardwood plywood is ideal. It’s strong, stable, and provides a reliable surface for waterproof membranes.

Why Plywood Is Preferred

Provides a smooth, even base for roofing materials.

Holds screws securely.

Resists swelling and delamination better than particleboard.

While some builders use OSB (Oriented Strand Board), plywood is often considered the better option for long-term durability and precision. It’s not necessary to use marine-grade plywood unless the specification requires it.

Dealing With Complex Roof Shapes

Flat roofs often have changes in level, steel beams, or intersecting roof sections. These require precise planning. At junctions where two roof planes meet, builders use compound mitre cuts — angled cuts that ensure the boards fit neatly even when the slope changes direction.

Edges must be eased off slightly (planed or sanded) to allow the roof membrane to lay flat over transitions. Patience and accuracy are key to maintaining drainage and waterproofing performance.

Importance of Planning Each Section

Every section of the roof — from joists to decking — must line up perfectly. One small error in spacing or leveling can cause issues later when installing insulation or waterproof layers.

Good planning includes:

Checking every measurement twice.

Allowing for insulation thickness.

Considering where gutters, gullies, and lanterns will sit.

Keeping all timbers clean and dry during construction.

This attention to detail ensures the final roof performs well and lasts longer.

Waterproofing and Finishing

Although the transcript focuses on timber framing, it’s worth noting what comes next. After the plywood deck is installed, the roof will be waterproofed using materials such as:

Torch-on felt (modified bitumen)

EPDM rubber membrane

Single-ply membrane

Each system has specific installation methods, but all rely on a perfectly flat, clean deck with the right falls and detailing around upstands and edges.

Common Mistakes to Avoid

Even small errors can affect the lifespan of a flat roof. Common mistakes include:

Incorrect falls – If the slope is too shallow or points the wrong way, water will pond.

Poorly fixed joists – Loose or twisted joists cause movement and cracks.

Skipping noggins – Without noggins, the deck can flex and weaken.

Overdriven screws – Screws buried too deep weaken fixings.

Uneven furring strips – Creates dips where water can collect.

Every stage must be done carefully to ensure the structure stays strong and watertight.

Why Proper Drainage Is So Important

Flat roofs rely entirely on controlled drainage. Without it, rainwater can stay on the surface, leading to:

Roof leaks

Rotting timber

Blistering in membranes

Mold and interior damp

Using furring strips to create a smooth fall eliminates these risks. Homeowners should check their roofs regularly after installation to make sure water is draining as intended.

Materials and Standards (UK Reference)

In the UK, flat roof construction should comply with the BS 6229:2018 and BS EN 1995 (Eurocode 5) standards for timber and drainage design.

Typical materials include:

Structural softwood timber (C16 or C24 grade)

Plywood or OSB 3 decking

Bituminous or polymer-based membranes

Galvanised screws and fixings

Following manufacturer and building regulation guidance ensures safety, performance, and longevity.

(Reference: British Standards Institution – BS 6229:2018: “Flat roofs with continuously supported flexible waterproof coverings – Code of practice”)

Final Checks Before Roofing

Before the waterproof membrane is installed, the builder checks that:

The deck is completely clean and dry.

All screws are flush or slightly below the surface.

The falls direct water to the right location.

Joints between boards are tight and supported.

Upstands and trimmers are sealed and square.

Once verified, the roof is ready for insulation and final waterproofing.

Benefits of a Well-Built Flat Roof

A properly constructed flat roof offers several advantages:

Modern appearance – Ideal for extensions and roof lanterns.

Easy maintenance – Access is simple for cleaning and inspection.

Energy efficiency – Works well with high levels of insulation.

Long life – With correct drainage and materials, lifespan exceeds 25 years.

These benefits only hold true when the structure is built with precision, using correct falls, solid joists, and durable materials.

Routine Maintenance for Homeowners

Once built, homeowners should maintain the flat roof to ensure lasting performance:

Inspect twice a year – Spring and autumn are best.

Keep gutters clear – Blocked drains cause ponding.

Check seals – Look for cracks around lanterns or upstands.

Look after surface finishes – Recoat or reseal as recommended.

Address pooling water early – Persistent ponding means the fall may need correction.

Regular care can prevent costly repairs and help identify small issues before they worsen.

Conclusion

A flat roof may look simple from above, but building one properly requires careful planning, accurate carpentry, and attention to every detail — from the first joist to the final slope.

Setting out the joists, securing the noggins, building the upstands, and shaping the furring strips are the foundations of a long-lasting roof. When each step is done right, the result is a structure that’s strong, well-drained, and ready to protect your home for decades.

References

British Standards Institution. (2018). BS 6229:2018 – Flat roofs with continuously supported flexible waterproof coverings – Code of practice.

NHBC (National House Building Council). (2022). Standards for Flat Roof Construction.

Timber Development UK. (2021). Timber Joists and Decking for Flat Roofs: Best Practice Guide.

Comments